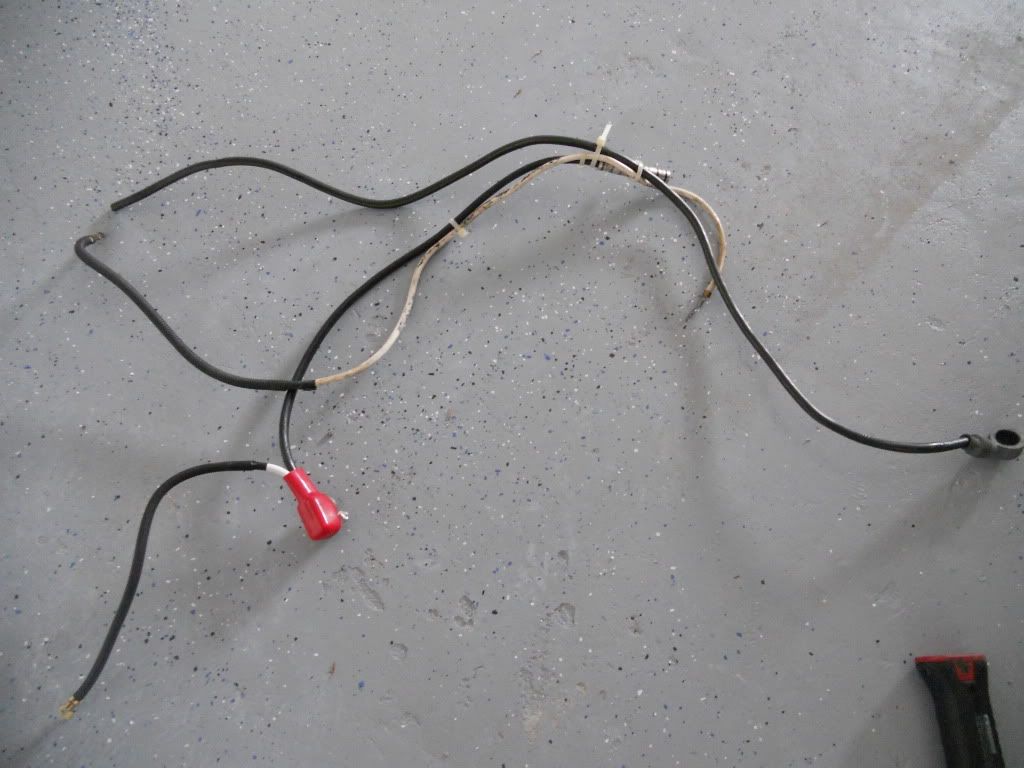

Well I've not really worked on my car in a while since I've been working on my brother's car instead. But I bit the bullet the other day and finished the short list of chores needed to finally make it run. I started out by finishing the charge harness for the battery. It is separate from the main harness for maintainence purposes. I bought a new Honda USDM one because of the battery terminals being different sizes.(picture lower).

Here is a picture of the new charge line and the JDM one which is extremely long. So I took the 2 and used some industrial crimps to join it together. Also I bought a 2.75" ID flange gasket.

Here is a rough look at the lengths I needed before it was finished.

Also a picture of the terminal ends for those who didn't know they were different sizes.

Here are my engine grounds. We have industrial crimps and all the ends so all I had to do to make the grounds was find a place to put them out of the way. Here's what I came up with.

right side

Left side

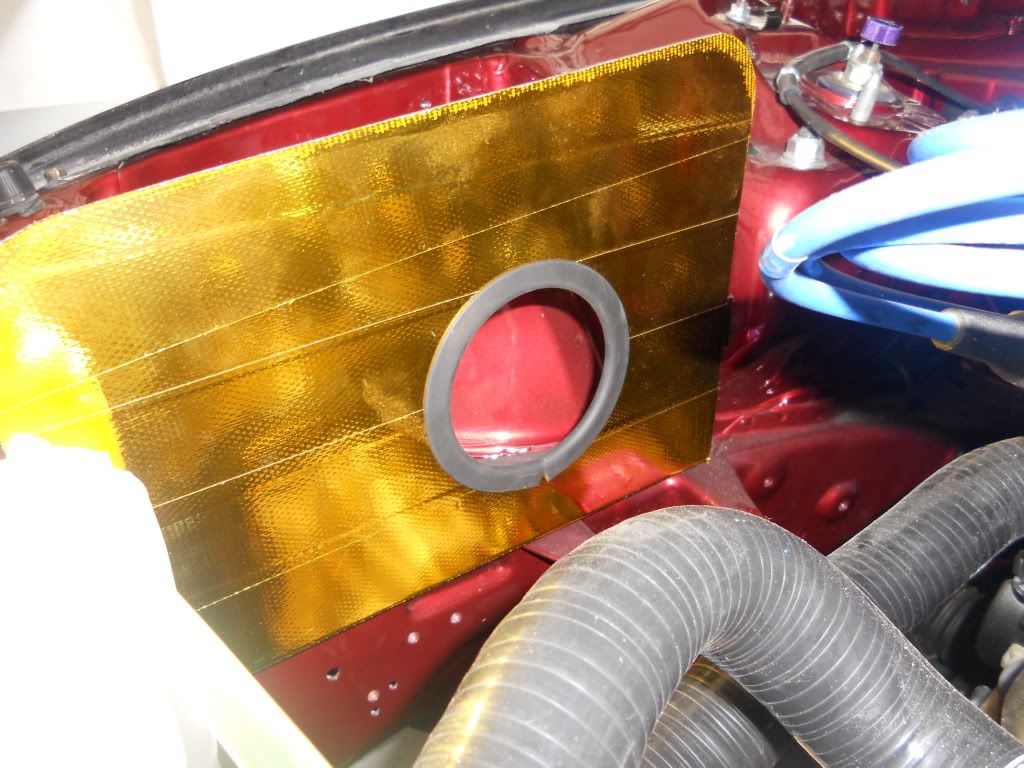

Also I had to modify the cooling plate I made because the header was about 1/4" away from it so I cut it back and repainted it. quick pic showing clearance now.

My Bisimoto header....

This is a subject that more and more people are having problems with. Saying that they make more power than the competitors is a white lie. Most lose huge power in the mid range. But the biggest thing is the lack of quality in this header. It looks okay but I heard that they now make these oversea's, Bisi doesn't even make them and Danny Tran makes his prototypes( I love my old SSR header btw). There is an obvious lack of craftsmanship in the welds. Looks like they got just someone who was "ok" with a TIG welder to make it. Hell the exhaust flange is crooked as s***. I had to cut the excess off so it would even bolt up to the test pipe. The product that I was going for was looks which it does fine in the department but it's just okay overall. And the concept that they are all "custom made" is silly. Someone in the business got told that one of the header's they recieved bisi had made 1300 exactly like it. It's more of a bit of thinking your header is specially made for you and just an overly priced, oversea's piece.

Also I got everything fixed enough and double checked everthing to make sure all the fluids and wiring were correct then I primed the fuel and oil then put the ecu back in and it fired right up. It sounds like my daily but just a little louder but since it has apexi ws2 it's still pretty silent. It has a vacuum leak around the throttle body so I've got to do something about that. No big deal just need to finish getting the ride height set because it's way too low. tucking tire is not for me.

Here is a picture of the new charge line and the JDM one which is extremely long. So I took the 2 and used some industrial crimps to join it together. Also I bought a 2.75" ID flange gasket.

Here is a rough look at the lengths I needed before it was finished.

Also a picture of the terminal ends for those who didn't know they were different sizes.

Here are my engine grounds. We have industrial crimps and all the ends so all I had to do to make the grounds was find a place to put them out of the way. Here's what I came up with.

right side

Left side

Also I had to modify the cooling plate I made because the header was about 1/4" away from it so I cut it back and repainted it. quick pic showing clearance now.

My Bisimoto header....

This is a subject that more and more people are having problems with. Saying that they make more power than the competitors is a white lie. Most lose huge power in the mid range. But the biggest thing is the lack of quality in this header. It looks okay but I heard that they now make these oversea's, Bisi doesn't even make them and Danny Tran makes his prototypes( I love my old SSR header btw). There is an obvious lack of craftsmanship in the welds. Looks like they got just someone who was "ok" with a TIG welder to make it. Hell the exhaust flange is crooked as s***. I had to cut the excess off so it would even bolt up to the test pipe. The product that I was going for was looks which it does fine in the department but it's just okay overall. And the concept that they are all "custom made" is silly. Someone in the business got told that one of the header's they recieved bisi had made 1300 exactly like it. It's more of a bit of thinking your header is specially made for you and just an overly priced, oversea's piece.

Also I got everything fixed enough and double checked everthing to make sure all the fluids and wiring were correct then I primed the fuel and oil then put the ecu back in and it fired right up. It sounds like my daily but just a little louder but since it has apexi ws2 it's still pretty silent. It has a vacuum leak around the throttle body so I've got to do something about that. No big deal just need to finish getting the ride height set because it's way too low. tucking tire is not for me.